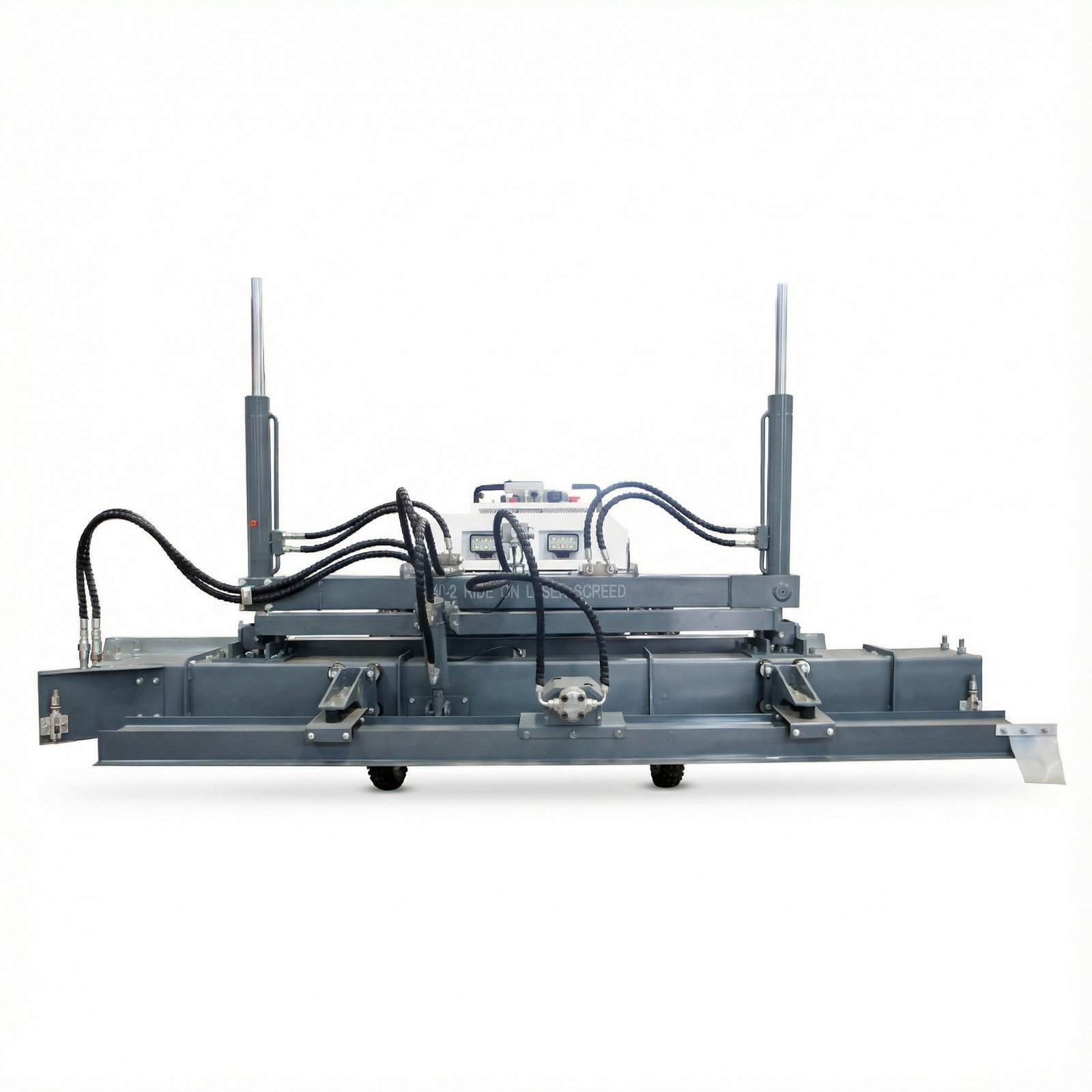

S840-2 Ride On Concrete Laser Screed Machine

$39,500.00

Four-wheel seated laser leveling machine (S-840-2 laser screed) has the following advantages:

1. Briggs Stratton engine:

capable of high-intensity work, more durable, better performance.

2. Hydraulic motor and hydraulic vibrating

High performance, high efficiency and high working pressure to meet the high requirements of application. Hydraulic vibrating is more powerful than electrical vibrating.

Specifications

| Engine | HONDA GX690 |

|---|---|

| Power | 23HP |

| Start up | Electric start |

| Fuel tank capacity | Gasoline 17L |

| Walking mode | Wheeled |

| Drive System | Hydraulic motor four-wheel drive |

| Drive control | Electric control hydraulic system |

| Paving method | Auger paving |

| Vibration frequency | 4000 times / minute |

| Vibration force | 2000N |

| Work efficiency | 200m2-500m2/hour |

| Laser control system | Leica brand |

| Elevation control | Double hydraulic cylinder |

| Laser control | Laser scanning |

| Control effect | Plane, slope or double slope |

| Maximum ground clearance | 330mm |

| Tire model | 100/900-21Anti-solid tire |

| Net weight | 1100kg |

| Machine size | 2880X2600X1040mm |

Features

![]()

Benefits

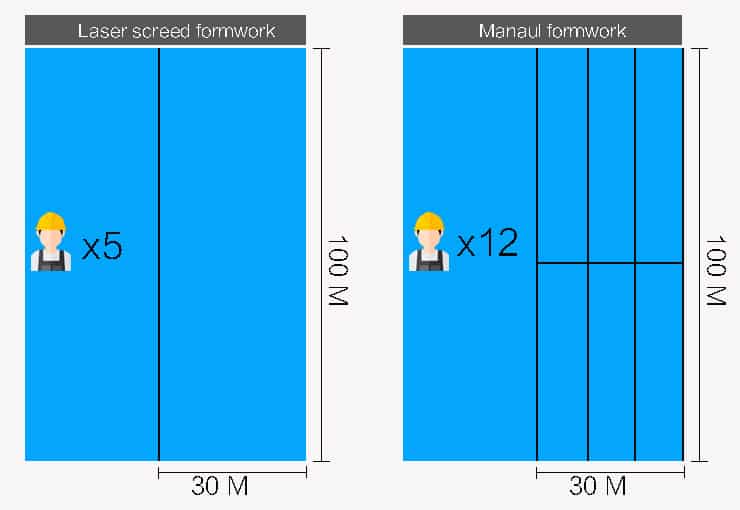

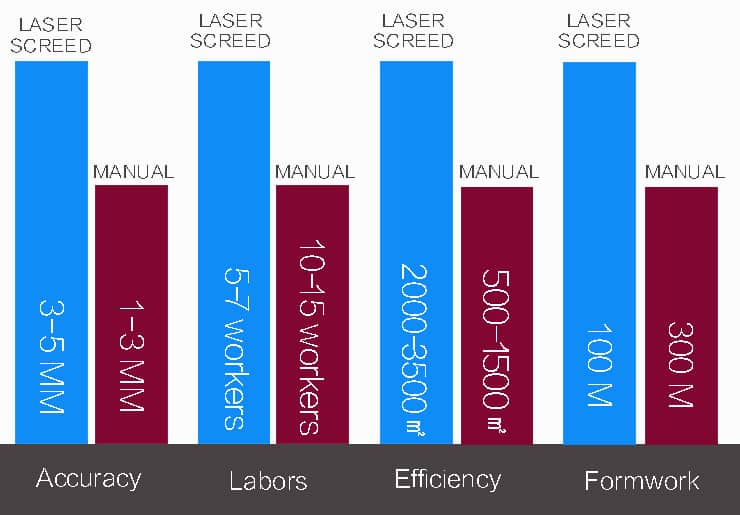

| Comparison Factor | Traditional Method | Laser Screed | Your Advantage |

|---|---|---|---|

| Labor Required | 20 workers | 4-8 workers (or 1 operator) | ↓ 70% labor costs |

| Daily Coverage | 800-1500㎡ | 2000-3500㎡ | ↑ 150-300% productivity |

| Precision | ±5-10mm (template-dependent) | ±1mm (laser-controlled) | 5-10X better accuracy |

| Floor Integrity | Segmented (construction joints) | Continuous large-area pouring | Superior flatness |

| Setup Time | 1 day formwork + 1 day pouring | Immediate operation | Faster project completion |

| Error Rate | High (template shock, cumulative) | Minimal (point-to-point laser) | Consistent quality |

Q&A

1. What is the quality of the machine?

HIKING places great emphasis on product quality, manufacturing and testing our machines according to a rigorous quality control system. The S840-2 comes with a one-year free warranty and lifetime cost guarantee (please refer to our warranty policy for specific details), ensuring you have complete peace of mind when using the machine.

2. What is the lead time?

The S840-2 is generally in stock. However, before leaving the factory, we conduct a secondary rigorous testing process and custom wooden crate packaging. The entire preparation cycle typically takes 7-10 working days.

3. How do I operate this machine? What if I don’t know how to use it?

In addition to written instructions, we have created detailed operation guide videos for the S740. By following the video content, you can easily learn how to operate the machine. If you have any specific questions during the process, you can always consult our technical staff for assistance.

4. How is the machine shipped? Can it be purchased in different countries?

We can ship to most countries worldwide. The S840-2 laser screed is a medium-sized piece of equipment and is typically transported by sea freight. If you would like to know specific delivery timeframes and shipping details, please leave a message in the form below to consult with our sales manager.

Get An Inquiry

If you need to know more about the Laser screed, you can leave your contact in the below from, We will contact you in 24 hours.